Description

ARCHITECTURAL ETFE FOILS

- Lightweight (weighs 1% of equivalent-sized glass panel).

- Highly transparent to UV light, not degraded by sunlight.

- Provides competitive insulation properties than glass.

- Can take up to 400 times its own weight.

- Is different to PVC & PTFE fabrics as it has no base cloth substrate; “extruded foil”.

- Typical construction is via an air supported pillow and pneumatic system.

ACOUSTIC PERFORMANCE

ETFE foil is acoustically transparent with a mass of less than 1kg/m2. As a result, it does not reflect internally generated noise back to the occupants. The internal environment is considerably more comfortable with shorter reverberation times than if the cladding had been constructed from an acoustically hard material.

- With a sound reduction index of less than 10dBA, the ETFE envelope can provide increased comfort levels & encourage occupants to make full use of the space.

TRANSPARENCY

ETFE Foil is naturally a very transparent material & transmits light across the entire visible light region (380-780nm). A single layer of medium weight ETFE has an approximate 85% light transmission, although multiple layers will lead to a small reduction. Transmission across the ultraviolet range (320- 380nm) is also very good (approx. 83-88%) and therefore allows plants and vegetation underneath to thrive. It is also important to note that the film absorbs a large proportion of infra-red light transmitted, a quality which can be exploited to improve buildings’ energy consumption.

SOLAR CONTROL

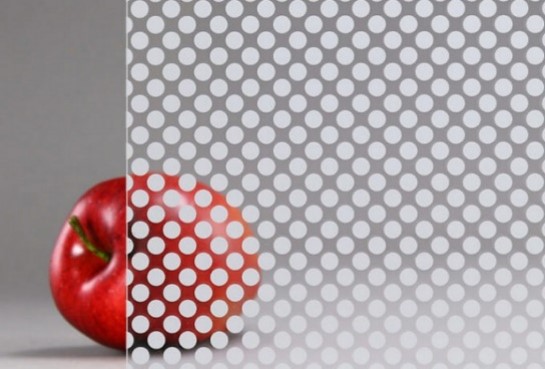

The base material of an ETFE installation is very transparent, however, the ETFE Foil can be treated in several different ways to manipulate its light transmission properties. One of those treatments include:

- Printing: Also known as fritting, the surface of the foil is covered with a variety of patterns to reduce solar gain while retaining translucency. By varying the percentage of coverage and density of the ink, the energy transmission can be altered. Alternatively, the foil can be overprinted with several treatments to affect transmission. We offer a variety of standard fritting patterns and bespoke patterns to achieve a variety of light LT% at an extra cost.

THE INVORONMENTAL IMPACT OF ETFE

RECYCLABILITY AND ENVIRONMENTAL IMPACT

100% recyclable and can be used to make products for industry such as pipes and valves without aesthetic and transparency requirements. Due to the useful life of the ETFE film (50+ years) the quantities of recycled material are extremely small and most of the recycled material currently comes from the processing waste of the new films.

DURABILITY

Thanks to its extraordinary resistance to UV radiation, pollution and meteorological agents, the ETFE film has an expected life exceeding 50 years, much longer than traditional plastics. When installed in architecture, the life spans expected exceeds 25 years.

ENVIRONMENTAL PRODUCT DECLERATION

In the literature there are several studies on the impacts of ETFE on the environment including LCA studies (Life Cycle Assessment) and EPD declarations (certified environmental product declaration).

ETFE is classified in class II by the Montreal Treaty with minimal damage to the ozone state. ETFE production takes place by transforming the TFE monomer into the ETFE polymer through a water-based polymerization process without the use of solvents. The material is then extruded in various thicknesses through an extrusion process that requires the use of minimal quantities of energy as well as the cutting and welding operations of the ETFE rolls for the packaging of the finished product.

Reviews

There are no reviews yet.